When it comes to maintaining a functional and efficient wastewater management system, choosing the right sewage pump system is paramount. As we enter 2025, the options available on the market have expanded significantly, making it essential for homeowners and businesses alike to understand the various features and specifications of each system. This guide aims to simplify the decision-making process, offering insights into what factors to consider when evaluating different sewage pump systems.

In this comprehensive overview, we will delve into the critical components of sewage pump systems, including types, installation requirements, and maintenance tips. By familiarizing yourself with these elements, you will be better equipped to select a system that aligns with your specific needs and ensures reliable performance. The importance of an effective sewage pump system cannot be overstated, as it plays a vital role in safeguarding your property and the environment from potential hazards associated with wastewater management. Join us as we explore the intricacies of selecting the best sewage pump system in 2025, and empower yourself with the knowledge to make an informed choice.

When selecting a sewage pump system, it's crucial to understand the various types and their specific functions.

Primarily, sewage pumps can be divided into two categories: submersible pumps and centrifugal pumps.

Submersible pumps are designed to operate while submerged in the sewage water they transport, making them ideal for situations where space is limited, such as in basements.

According to the Water Environment Federation, approximately 85% of residential pump systems installed in the U.S. in 2020 were submersible, primarily due to their energy efficiency and reduced noise levels.

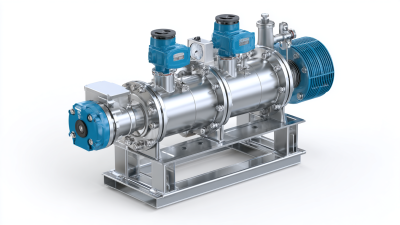

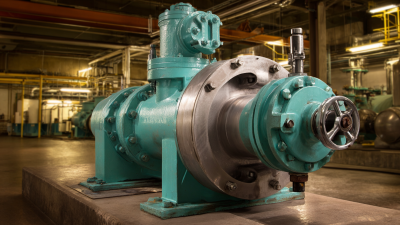

On the other hand, centrifugal sewage pumps are typically used for larger applications.

They utilize a rotating mechanism to move water, making them more suited for higher volume discharges.

A report published by the American Society of Civil Engineers highlighted that centrifugal pumps account for around 75% of the sewage pump market in industrial and municipal installations due to their robustness and ability to handle solid waste.

Understanding these functional differences is vital for making an informed decision when choosing a sewage system that best meets your needs, especially with the evolving technologies and regulations expected in 2025.

When selecting a sewage pump system, several key factors must be considered to ensure the system meets your needs and operates efficiently. First and foremost, understanding the flow rate and the lift height is crucial. The flow rate, measured in gallons per minute, determines how quickly the pump can transport waste away from your property. Meanwhile, lift height, or the vertical distance the pump must move waste, will affect the pump's performance and energy consumption. It’s essential to choose a pump that can handle the specific requirements of your sewage system without being over or underpowered.

Another important factor to take into account is the type of sewage that the pump will handle. Different pumps are designed for various types of waste, from simple wastewater to more complex mixtures containing solids. Assessing the size and types of solids, as well as the potential for clogging, can guide you in selecting a pump with suitable capabilities. Additionally, consider the materials used in the pump's construction. Pumps made from durable, corrosion-resistant materials will ensure longevity and reliability, especially in environments where they will face harsh conditions. Understanding these factors will help you make an informed decision when investing in a sewage pump system.

When selecting a sewage pump system in 2025, it's imperative to compare models based on performance, efficiency, and reliability. According to a report published by the American Society of Civil Engineers, approximately 25% of all water infrastructure projects require upgrading to handle modern sewage loads. This statistic underscores the importance of choosing a pump system that can not only handle current demands but also anticipated future requirements. Leading models in the market are increasingly designed with advanced engineering solutions, including corrosion-resistant materials and energy-efficient motors, which can significantly impact long-term operational costs.

Furthermore, a 2021 industry analysis by Market Research Future indicated that the global sewage pump market is projected to grow by 6% annually, reflecting a rising demand for innovative solutions in waste management. Comparing sewage pump systems involves analyzing specifications like horsepower, maximum flow rates, and operational noise levels, which are integral to proper functionality in residential and commercial settings. Systems equipped with smart technology for monitoring performance and predictive maintenance features are becoming more common, highlighting the trend towards automation in this industry. Evaluating these aspects will ensure that consumers can select the most suitable sewage pump model for their specific needs in the evolving landscape of 2025.

| Model | Power (HP) | Max Flow Rate (GPM) | Max Head (Feet) | Material | Warranty (Years) | Price ($) |

|---|---|---|---|---|---|---|

| Model A | 1/2 | 50 | 30 | Cast Iron | 2 | 300 |

| Model B | 3/4 | 60 | 28 | Stainless Steel | 3 | 450 |

| Model C | 1 | 70 | 25 | Polypropylene | 5 | 550 |

| Model D | 1.5 | 80 | 40 | Cast Iron | 4 | 650 |

Maintaining a sewage pump system is crucial for ensuring its longevity and optimal performance. Regular maintenance can prevent unexpected breakdowns, which can lead to costly repairs and inconvenient disruptions. According to industry reports, nearly 75% of sewage pump failures are attributed to a lack of proper maintenance. To avoid these issues, pump owners should adhere to a comprehensive maintenance schedule that includes regular inspections, cleaning, and lubrication of all moving parts.

Tip: Check the pump's float switch regularly to ensure it operates correctly. A malfunctioning float switch can lead to continuous operation, which may cause overheating and damage to the pump over time. Additionally, inspecting and cleaning the pump filter can prevent debris buildup that could block the flow, ensuring efficient operation.

It's also important to monitor the power supply and connections to avoid electrical issues that could cause pump failure. Regularly checking the discharge line for clogs and wear can prevent backups that compromise the system's efficiency. Professional reports recommend that sewage pumps be serviced at least once a year, but more frequent checks may be necessary in vulnerable environments.

Tip: Keep a maintenance log. Documenting inspections, repairs, and any issues that arise can help identify patterns and prevent future problems, ultimately extending the life of the sewage pump system. By prioritizing these maintenance practices, homeowners and facility managers can safeguard their investments and ensure reliable wastewater management.

This chart represents the average lifespan (in years) of different types of sewage pump systems based on maintenance frequency. Regular maintenance significantly impacts the longevity of these systems.

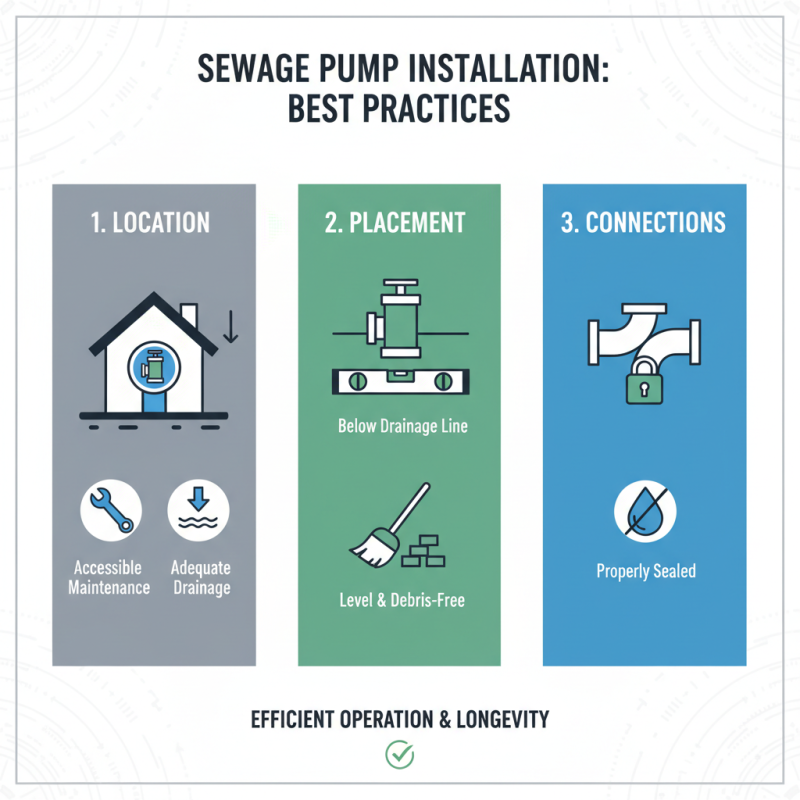

When installing a sewage pump system, adhering to best practices is crucial to ensure efficient operation and longevity. First, it is vital to choose an appropriate location for the pump that is both accessible for maintenance and offers adequate drainage. The installation site should be level and free from debris to prevent any blockages or mechanical issues. Additionally, ensure that the sewage pump is installed below the drainage line to facilitate proper flow without the risk of backflow. Properly sealing all connections will help prevent leaks and ensure that the system operates effectively.

Common mistakes during installation can lead to significant problems down the line. One frequent error is neglecting to follow the manufacturer’s specifications regarding pipe size and fitting connections, which can result in inadequate pumping capacity or overworking the pump. It’s also essential to avoid placing the pump too close to materials that may obstruct airflow, such as vegetation or structural elements. Lastly, failing to install a reliable power supply and backup system can lead to failures during power outages. Taking the time to consider these best practices and avoiding common pitfalls will help create a reliable and efficient sewage pump system.

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com