In industrial settings, pumps serve as essential components for the smooth operation of various equipment. However, like any mechanical system, pumps can experience wear and tear over time, leading to reduced efficiency and potential failures. This is where pump repair comes into play. Understanding the significance of pump repair not only helps in maintaining the operational effectiveness of your equipment but also extends its lifespan, thereby ensuring optimal performance.

Neglecting to address pump-related issues can result in costly downtimes and expensive replacements. By prioritizing routine maintenance and timely repairs, businesses can minimize disruptions and maintain a productive workflow. Pump repair is not just a reactive measure; it is a proactive approach to safeguarding your investments. With knowledgeable technicians on hand to assess and rectify any arising issues, the longevity of your equipment can be dramatically improved, contributing to overall operational success.

Investing in pump repair can lead to significant cost savings in the long run. It enhances system reliability, boosts energy efficiency, and ultimately translates to better service delivery. This article will explore the importance of pump repair and the various ways it can support the longevity of your equipment, ensuring that you remain competitive in today’s fast-paced industrial landscape.

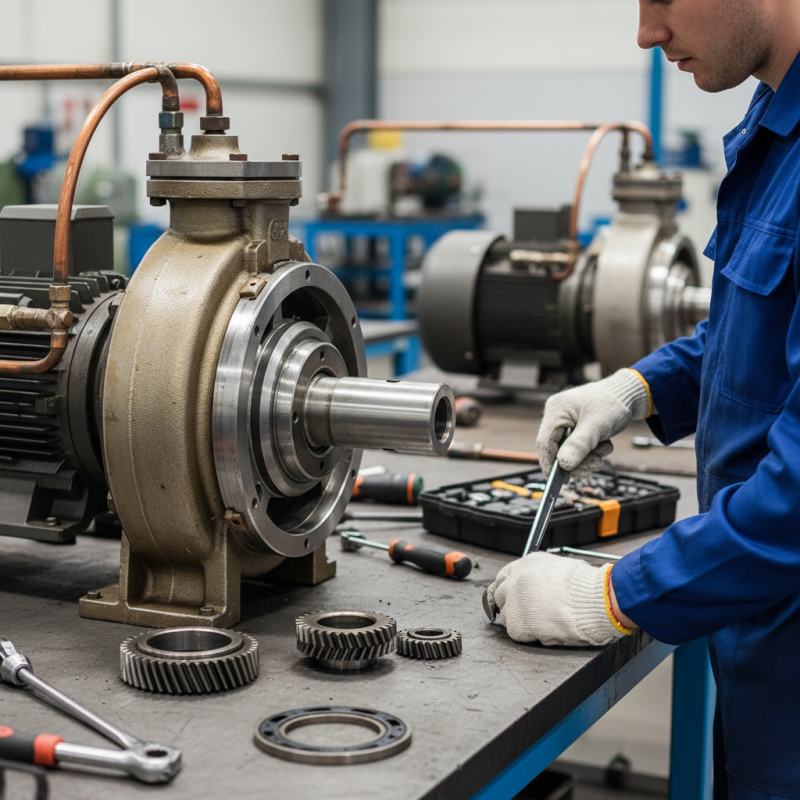

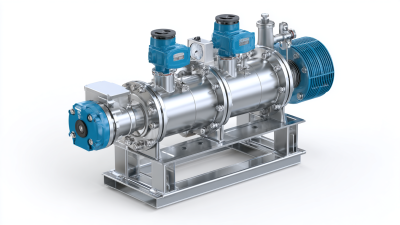

Pump repair and maintenance are essential to ensure the longevity and efficiency of your equipment. Understanding the basics of pump repair involves knowing how to identify common issues, perform regular inspections, and take preventative measures. Pumps can suffer from wear and tear over time, leading to decreased performance and ultimately, equipment failure. Thus, establishing a routine maintenance schedule is crucial. This includes checking seals, bearings, and impellers for any signs of damage or corrosion.

**Tips for Effective Pump Maintenance:**

1. Regularly inspect your pumps for leaks or unusual noises, as these can be early signs of trouble.

2. Keep a log of maintenance activities to track performance trends over time and anticipate potential issues.

3. Implement a lubrication schedule as per manufacturer guidelines to ensure smooth operation and reduce friction.

By proactively addressing potential problems through simple maintenance procedures, you can significantly extend the lifespan of your pumps and avoid costly repairs down the line. Regular maintenance not only enhances reliability but also optimizes the overall performance of your equipment.

When it comes to maintaining the efficiency of your equipment, paying attention to your pump is crucial.

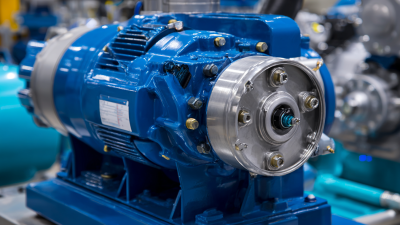

Common signs indicating your pump requires repair can prevent larger issues down the line. One significant warning sign is unusual noise during operation.

If your pump begins to produce grinding, squealing, or excessive humming, it may be indicative of wear and tear in its components or misaligned parts.

Another red flag is a decrease in performance or pressure. If you're noticing fluctuations in flow rates or a drop in pressure, this could suggest that the internal mechanisms are not functioning correctly.

Additionally, leaks around the pump housing can signal that seals are damaged, which compromises the system’s integrity.

Addressing these issues promptly will not only extend the lifespan of your pump but will also ensure that your equipment operates smoothly and efficiently,

saving you both time and resources in the long run.

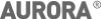

The pump repair process is essential for maintaining the efficiency and longevity of equipment, particularly in industries where pumps are critical for operations. According to the Hydraulic Institute, improper maintenance can reduce pump efficiency by up to 20%, significantly increasing operational costs. The repair process begins with a thorough inspection to identify issues such as leaks, wear, or vibrations. This step is crucial as it allows technicians to pinpoint the root causes of malfunction and plan effective solutions.

Once the inspection is complete, the next phase involves disassembly and cleaning of the pump components. Reports from the American Society of Mechanical Engineers highlight that regular cleaning can enhance pump performance and prevent premature failures, extending service life by as much as 30%. After cleaning, worn-out parts are replaced, and the pump is reassembled. Finally, testing is conducted to ensure that the pump is operating at optimal capacity. By following this structured repair process, facilities can significantly reduce downtime and maintenance costs while improving the overall reliability of their equipment.

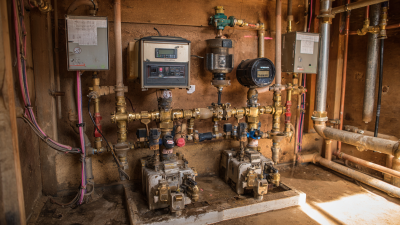

Regular pump maintenance is crucial for ensuring the longevity of your equipment. By implementing a consistent maintenance schedule, you can prevent costly breakdowns and extend the lifespan of your pumps. Scheduled inspections allow for the early detection of wear and tear, helping to address minor issues before they escalate into significant problems. This proactive approach not only saves money in the long run but also enhances overall operational efficiency.

Additionally, maintaining pumps can improve their performance and reliability. Well-maintained pumps operate more smoothly, leading to reduced energy consumption and lower operational costs. Regular maintenance tasks, such as lubrication, cleaning, and parts replacement, help keep the equipment running at peak performance. Moreover, when pumps are well cared for, the risk of unexpected failures decreases, ensuring a more stable production environment and increasing your overall productivity. Investing in regular pump maintenance is, therefore, a wise choice for any business looking to sustain equipment integrity and performance over time.

When it comes to maintaining the efficiency and longevity of your equipment, understanding when to seek professional help for pump issues is crucial. Pumps play a vital role in various systems, and any malfunction can lead to significant operational disruptions. If you notice unusual noises, leaks, or a drop in performance, it’s time to consult an expert. Ignoring these signs can result in more severe damage and costly repairs down the line.

Tips for maintaining your pump include conducting regular inspections and cleaning to prevent buildup that may hinder performance. Additionally, keep an eye on the pump's pressure levels; erratic fluctuations may indicate underlying issues. It’s also wise to establish a routine maintenance schedule with a qualified technician, ensuring that your pumps receive the attention they need before minor issues escalate into major problems. Proactive care will not only enhance the lifespan of your equipment but also guarantee its optimal performance.

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com