Efficient pump systems are critical components in various industrial applications, from water treatment to chemical processing. According to a recent report by the International Pump Industry Federation, the global pump market is projected to grow at a CAGR of 5.6% from 2021 to 2027, underscoring the increasing importance of optimizing these systems for performance and cost-effectiveness. With energy efficiency becoming a paramount concern, experts in the field emphasize the need for effective management to enhance operational efficiency.

Dr. Amanda Stevens, a leading expert in fluid dynamics and pump technology, states, "The performance of pump systems directly impacts overall system efficiency and operational costs." This highlights the necessity for industries to adopt best practices and innovative approaches in the design and maintenance of their pump systems. By implementing essential tips and strategies, businesses can not only reduce energy consumption but also extend the lifespan of their equipment. As industries strive to meet sustainable practices and reduce carbon footprints, understanding and improving the function of pump systems will be key in driving both financial and environmental benefits.

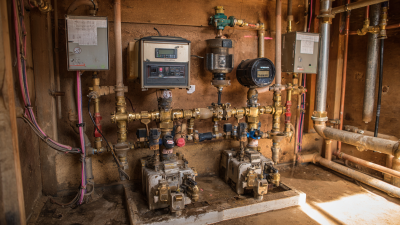

Understanding the Basics of Pump Systems is crucial for anyone looking to optimize their efficiency and performance. At the core of any effective pump system lies the principle of fluid dynamics, which governs how fluids move under various conditions. Understanding concepts such as flow rate, head pressure, and the characteristics of different types of pumps can significantly influence the selection and operation of a pump. Whether you are working with centrifugal pumps, positive displacement pumps, or submersible pumps, each type has its own unique attributes and optimal operating conditions that need to be comprehended for maximum efficiency.

Another pivotal aspect of mastering pump systems is the role of system design and layout. Proper planning of the piping system, including sizing, materials, and route, can affect the overall efficiency and lifespan of the pump. Attention to factors such as minimizing bends and using the appropriate pipe diameter helps reduce frictional losses, leading to improved energy efficiency. Regular maintenance practices, including monitoring for wear and tear, can also help ensure that the pump operates within its desired parameters. By focusing on these fundamental principles, individuals and organizations can better manage their pump systems, reduce operational costs, and enhance overall system reliability.

| Tip Number | Tip Description | Importance |

|---|---|---|

| 1 | Regularly check the pump for any signs of wear and tear. | High |

| 2 | Ensure the pump is properly sized for the application. | Critical |

| 3 | Maintain proper fluid levels to avoid pump damage. | High |

| 4 | Use quality seals and gaskets to prevent leaks. | Medium |

| 5 | Install a pressure gauge to monitor system performance. | High |

| 6 | Schedule regular maintenance to avoid unexpected failures. | Critical |

| 7 | Ensure proper electrical connections to prevent power issues. | Medium |

| 8 | Keep the pump and surrounding area clean and free from debris. | Medium |

| 9 | Monitor energy consumption to identify potential savings. | High |

| 10 | Train staff on proper pump operation and safety protocols. | Critical |

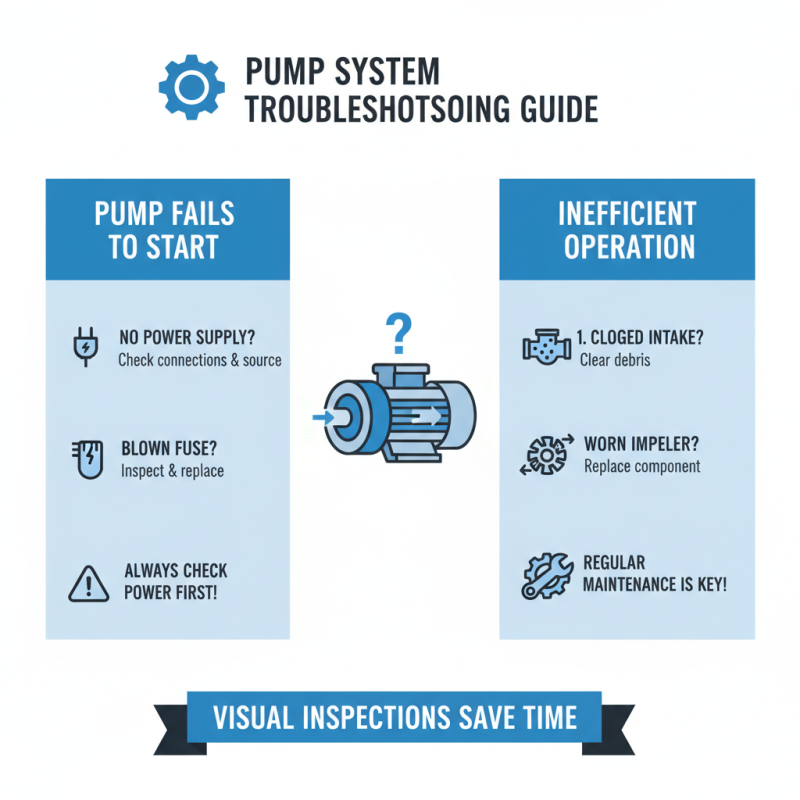

An efficient pump system is essential for optimizing performance and reducing operational costs in various industrial applications. The key components that contribute to the efficiency of a pump system include the pump itself, the motor, piping, and control systems. Selecting the right pump type based on the specific application requirements—such as flow rate, total dynamic head, and fluid characteristics—is crucial. A well-matched pump will not only enhance efficiency but also prolong the lifespan of the equipment by minimizing wear and tear.

Another critical aspect is the motor, which drives the pump. The efficiency of the motor directly affects the overall system performance. It is vital to choose a motor that aligns with the pump's requirements and is capable of operating under varying load conditions. Additionally, incorporating proper piping design—including correct sizing, layout, and materials—can significantly reduce friction losses, ensuring that the fluid moves smoothly through the system. Automated control systems can further optimize performance by adjusting the flow rate and pressure dynamically, leading to energy savings and consistent operation. Together, these components create a streamlined pump system that is both cost-effective and reliable.

Proper sizing and selection of pumps is crucial for the efficient operation of pump systems. When pumps are not sized correctly, it can lead to a variety of issues, including reduced efficiency, increased energy consumption, and premature wear and tear. An oversized pump can operate at an inefficient point on its performance curve, resulting in wasted energy and increased operational costs. Conversely, an undersized pump may struggle to meet the required flow rate, which can cause cavitation and damage to the pump, ultimately leading to system failure.

To ensure optimal performance, it is essential to thoroughly evaluate the specific requirements of the application before selecting a pump. This includes considering factors such as flow rate, pressure, temperature, and the characteristics of the fluid being pumped. Additionally, understanding the total dynamic head (TDH) is critical to accurately sizing the pump, as it represents the energy required to move the fluid through the system, accounting for friction losses and elevation differences. By dedicating time and resources to the proper sizing and selection process, organizations can enhance system reliability, reduce maintenance costs, and maximize overall efficiency.

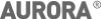

Effective maintenance practices are crucial for enhancing the performance of pump systems, which play a vital role in various industrial operations. According to a report by the Hydraulic Institute, inadequate maintenance can lead to efficiency losses of up to 30%, significantly impacting operational costs. Regular maintenance not only increases the lifespan of pump systems but also ensures optimal performance, which can be achieved through systematic inspections, timely repairs, and routine cleaning.

Implementing a proactive maintenance schedule that includes vibration analysis and thermal imaging can identify potential issues before they escalate. The American Society of Mechanical Engineers (ASME) highlights that such predictive maintenance techniques can prevent unexpected downtime, which, according to industry studies, can cost businesses upwards of $250,000 per hour in lost productivity. Additionally, proper lubrication and regular monitoring of pump seals and bearings are essential to maintain operational efficiency and reduce wear and tear. By adopting these maintenance practices, organizations can significantly improve the reliability and efficiency of their pump systems, ultimately leading to lower energy consumption and reduced operational costs.

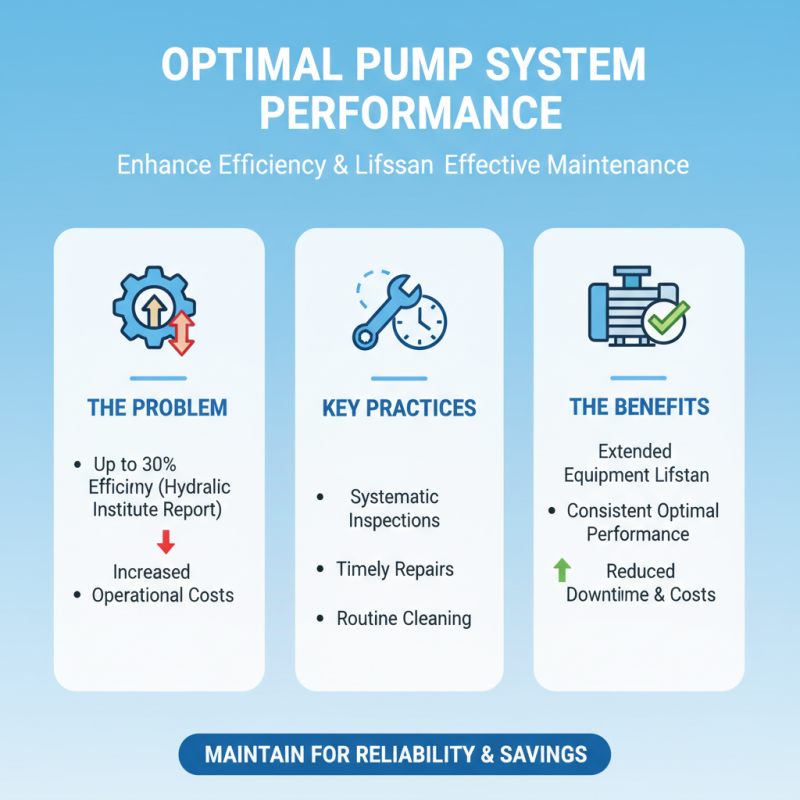

When dealing with pump systems, troubleshooting can often become a daunting task. One common issue is the failure to start, which may be due to insufficient power supply or a blown fuse. Before diving into more complex solutions, it’s crucial to check the power source, ensuring that all connections are secure and functioning. If the pump starts but operates inefficiently, this might indicate a clog in the intake or a worn-out impeller. Regular maintenance and visual inspections can help identify such issues early on.

Another frequent problem concerns unusual noise, which could suggest mechanical faults or cavitation. Listening carefully to the pump's operations can provide insight into underlying issues. If you hear grinding or rattling sounds, it’s essential to investigate further, potentially indicating that bearings need lubrication or replacement. Additionally, monitoring the pressure readings can reveal whether the pump is generating the expected output. Keeping a detailed log of these assessments can aid in recognizing patterns over time, allowing for proactive maintenance that reduces downtime and enhances system efficiency.

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com