In today's industrial and agricultural landscape, choosing the right suction pump is crucial for optimizing efficiency and productivity. According to a recent report by Market Research Future, the global suction pump market is anticipated to grow at a CAGR of 5.7% from 2021 to 2027, reflecting the increasing demand across sectors such as wastewater management, construction, and chemical processing. This growth underscores the importance of making informed decisions when selecting a suction pump tailored to specific applications and needs.

Expert insights also highlight the significance of understanding your requirements before purchasing. Dr. Emily Cheng, a renowned suction pump technology expert, states, “Selecting the proper suction pump not only enhances operational efficiency but also reduces long-term maintenance costs.” This quote emphasizes the critical nature of tailoring your choice of suction pump to the intended use, whether it's for transferring liquids, removing waste, or other applications.

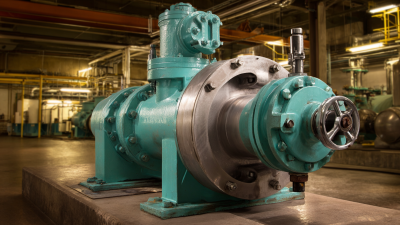

As industries continue to evolve, the variety of suction pumps available reflects advancements in technology and engineering. Understanding the diverse types of suction pumps, their specific functionalities, and the nuances involved in selection will empower users to make well-informed decisions, ensuring optimal performance and reliability in their operations.

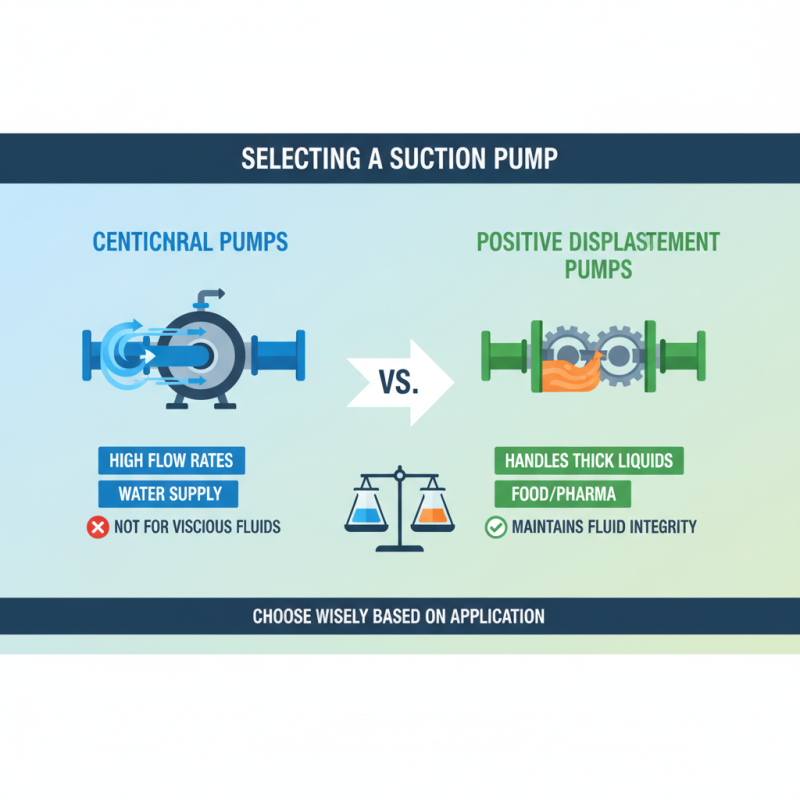

When selecting a suction pump, it's important to understand the different types available and their specific applications. Centrifugal pumps, commonly used in water supply systems, can deliver high flow rates but are not suitable for viscous fluids. In contrast, positive displacement pumps are ideal for handling thick liquids, making them favorable in industries such as food processing and pharmaceuticals, where maintaining fluid integrity is crucial.

Diaphragm pumps offer the ability to handle corrosive and abrasive materials effectively, which makes them perfect for chemical processing. A report by the Global Pump Market Analysis indicates that the diaphragm pump segment is expected to grow significantly, driven by increasing demand in diverse industries. Similarly, peristaltic pumps, with their ability to pump sterile fluids without contamination, are widely used in medical and laboratory applications.

Tips: When choosing a suction pump, consider the fluid's viscosity and temperature, as these factors greatly influence pump efficiency and lifespan. Additionally, always evaluate the pump's compatibility with the materials being processed to avoid corrosion or damage. Regular maintenance checks will also enhance the pump's performance and reliability, ensuring it meets operational demands efficiently.

When selecting the right suction pump for your applications, several factors come into play to ensure optimal performance and efficiency. First and foremost, it is essential to identify the type of fluid you will be handling. Different fluids, such as water, oil, or chemicals, may require different pump materials and designs to avoid corrosion or damage. Additionally, the viscosity and temperature of the fluid can significantly impact pump choice; thicker fluids or those at extreme temperatures may need specialized pumps to maintain effective flow and prevent overheating.

Another crucial consideration is the required flow rate and suction lift. Understanding the necessary capacity and the vertical distance the pump must lift the fluid will help narrow down the options. It's also important to consider the operational environment, including factors like space constraints and potential exposure to harsh conditions. Evaluating whether the pump will be used for continuous or intermittent operation can also influence your selection, as some designs are more suited for cyclical tasks. By thoroughly assessing these criteria, you can choose a suction pump that meets your specific needs and ensures reliable operation.

| Factor | Description | Considerations |

|---|---|---|

| Application Type | Identify what the pump will be used for (e.g., water, chemicals, slurries). | Different pumps are suited for different materials and viscosities. |

| Flow Rate | Determine the required flow rate (volume per unit time). | Choose a pump that can handle the necessary flow without overloading. |

| Head Pressure | Calculate the vertical height the liquid needs to be lifted. | Ensure the pump can sustain the required head pressure. |

| Power Source | Identify if the pump is electric, gasoline, or pneumatic. | Consider availability of power and operational convenience. |

| Portability | Evaluate if the pump needs to be moved frequently. | Select lightweight or compact models for easier transport. |

| Cost | Assess your budget for purchasing and maintaining the pump. | Balance between initial cost and long-term reliability/maintenance. |

| Material Compatibility | Ensure the materials used in the pump are compatible with the liquid. | Avoid corrosion or damage by selecting materials accordingly. |

When selecting a suction pump for specific needs and applications, evaluating the performance metrics is crucial to ensure efficiency and reliability. Key performance indicators to consider include the flow rate, which measures the volume of fluid that the pump can transfer within a specific timeframe. A higher flow rate is often desirable for applications requiring quick fluid removal or transfer; however, it is vital to match this metric with the demands of the particular job, as excessive flow can cause turbulence and inefficiency.

Another important metric is the suction lift, which refers to the height to which the pump can draw liquid from the source. Understanding the maximum suction lift capability is essential for ensuring that the pump will perform adequately in its intended environment, especially in applications involving deep reservoirs or high elevations. Additionally, the pump's power consumption and efficiency ratings should be assessed to minimize operational costs and ensure sustainable usage over time. Ultimately, a thorough evaluation of these performance metrics will aid in selecting the right suction pump that aligns with both operational needs and economic considerations.

Proper maintenance and care are crucial for ensuring optimal functionality of a suction pump. Regular inspection should start with checking the pump's seals, hoses, and fittings for any signs of wear or damage. Any leaks can significantly affect the suction power and efficiency of the pump. It's also important to maintain a clean environment around the pump to prevent dust and debris from entering the system, which could lead to clogs and performance issues. Proper storage when not in use—keeping the pump in a dry, low-humidity area—also contributes to its longevity.

In addition to preventive checks, routine maintenance tasks such as lubrication of moving parts and replacing filters should not be overlooked. Follow the manufacturer's guidelines for servicing the pump, including any recommended intervals for part replacement. A regular maintenance schedule helps identify potential problems before they escalate, ensuring the suction pump operates efficiently. If any unusual noises or vibrations are detected during operation, these should be investigated immediately, as they may signal underlying issues that could impair the pump's performance. By prioritizing maintenance, users can maximize the lifespan and reliability of their suction pumps.

When selecting a suction pump, it's essential to avoid common pitfalls that can lead to inefficiencies or malfunctions. One prevalent mistake is failing to accurately assess the application's requirements. Understanding the specific fluid characteristics—such as viscosity, temperature, and corrosiveness—can dramatically influence pump performance. Additionally, not considering the required flow rate and suction lift can lead to the selection of an inadequate pump for the job.

Tip: Before making a decision, conduct a thorough analysis of your application's needs. This includes assessing the physical properties of the fluid to ensure compatibility and performance efficiency.

Another frequent error is neglecting the pump's maintenance needs. Some pumps may require extensive upkeep, which can be time-consuming and costly. If maintenance is overlooked, it can result in reduced lifespans and unexpected downtimes, affecting overall productivity. Choosing a pump that balances ease of maintenance with reliability is crucial.

Tip: Look for pumps that offer user-friendly maintenance features or those with readily available support and service information, as this can save time and resources in the long run.

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com