Choosing the right sewage pumps is essential for efficient wastewater management. According to industry expert John Matthews, “Selecting the right sewage pump can save you time and money.” His words emphasize the importance of making informed decisions.

Sewage pumps come in various types and capacities. Understanding your specific needs is crucial. You must consider the volume of wastewater and the distance it needs to travel. Many overlook power requirements, which can lead to operational issues over time.

It's tempting to opt for the cheapest option available. However, this can lead to frequent breakdowns. Reflecting on your choices could result in greater efficiency and long-term savings. Evaluating different models and brands is necessary for finding the right sewage pump.

When selecting sewage pumps, understanding their types is critical. There are three main categories: submersible, pedestal, and grinder pumps. Submersible pumps are designed to work underwater, efficiently pumping waste from a submerged location. They are compact and can handle solids. However, they may require more maintenance than other options.

Pedestal pumps, on the other hand, sit above the water level. They are easier to service but can be noisy. These pumps are suitable for residential areas with minimal solid waste. Meanwhile, grinder pumps can handle tougher solids. They grind waste before pumping it, making them ideal for homes with plumbing challenges. Yet, their complexity might lead to issues over time.

Evaluating your specific needs can be tricky. Consider the type of waste, the pump location, and maintenance capability. You might overlook the importance of horsepower. Sometimes, it’s better to choose a less powerful pump if the environment allows. Each pump type has strengths and weaknesses. Make sure to reflect on your situation before deciding.

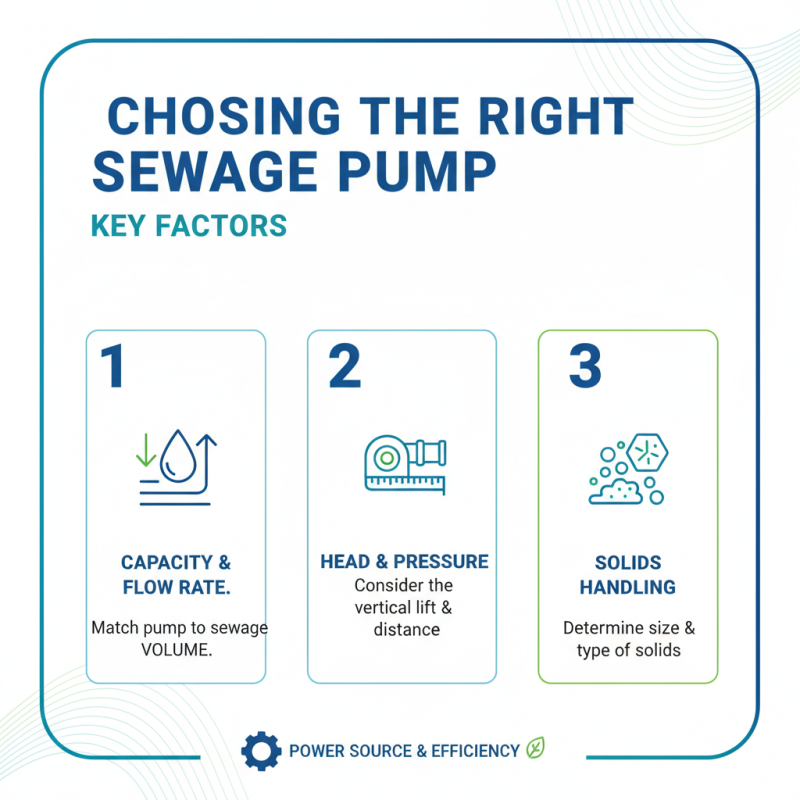

Choosing the right sewage pump requires attention to several key factors. Start with the pump's capacity. Understand the volume of sewage that needs to be pumped. Consider the flow rate required for your project. A pump that is too small will struggle, while one that's too large may waste energy.

Another critical aspect is head height. This refers to the vertical distance the pump must lift the sewage. If the head height is underestimated, the pump will not perform efficiently. Think about the type of waste it will handle, too. Some pumps are better for solids, while others manage liquids only.

Durability is important as well. Look for materials that can withstand harsh conditions. Factors like temperature and chemical exposure matter. You may face challenges finding the perfect fit, as many pumps may not meet all your needs. Reflect on the long-term maintenance and repair possibilities, as these can impact overall costs and project success.

When choosing a sewage pump, key specifications play a crucial role in performance. Horsepower directly impacts the pump's ability to handle larger volumes. A higher horsepower means more power, but it may also lead to higher energy costs. Evaluating your needs thoroughly is necessary. You don’t want to overspend on power you don’t need.

Flow rate is another essential factor. It measures the volume of water the pump can move in a given time. A pump with an inadequate flow rate may leave you with standing water. However, too high of a flow rate can overwhelm your system. Striking a balance is vital for efficient drainage.

Head—the vertical distance the pump can raise water—matters significantly. Each application has specific head requirements. Ignoring this detail may lead to subpar performance. Many users estimate without proper calculations, often leading to pump failure. It’s easy to overlook these specifications, but doing so can have costly consequences. Always reflect on your specific situation and make decisions accordingly.

When selecting sewage pumps, material choice is crucial. The durability of the material directly affects the pump's longevity. Common materials include cast iron, stainless steel, and thermoplastic. Each has pros and cons. Cast iron is robust and offered for heavy-duty applications. However, it can corrode over time and may require maintenance. Stainless steel resists corrosion but can be costlier. Thermoplastic is lightweight and affordable but may wear out under extreme conditions.

Tips: Always assess the environment where the pump will operate. High temperatures or corrosive substances demand a stronger material. Additionally, consider the pump's performance requirements. Underestimating this can lead to failures.

Evaluate the manufacturer's recommendations. Sometimes, less popular materials might actually outperform traditional options. Conducting thorough research is essential. Don't rush into decisions based only on price. Long-term investment pays off with reliable equipment. Imperfections in choices can lead to costly repairs. Reflect on priorities: efficiency, maintenance, and cost over time. This focus can save headaches in the future.

Regular maintenance is essential for increasing the lifespan of your sewage pump. According to the National Association of Home Builders, a well-maintained pump can last up to 10 years longer than one that is neglected. Start by checking the pump for any unusual noises or vibrations, which could indicate mechanical issues. Inspect the power supply and ensure connections are secure. Clean out debris and buildup around the inlet and impeller, as clogs can lead to operational failures.

Oil changes are often overlooked. Periodic oil changes are crucial for pumps that use lubricant. Refer to the manufacturer’s guidelines for frequency. Industry data suggests that pumps with regular oil changes see a 25% increase in efficiency. Additionally, testing the float switch regularly can prevent potential pump failures. If the float gets stuck, your pump might not activate when needed, leading to flooding or backup issues.

Consider professional inspections once a year. Many homeowners skip this, which can be a costly mistake. It's a proactive step that can save you from unexpected breakdowns. Keeping detailed maintenance records can help track any recurring issues. Reflect on past repairs; you may identify patterns that require attention. This mindful approach can ultimately ensure that your sewage pump operates efficiently for many years.

| Dimension | Description | Recommended Values |

|---|---|---|

| Flow Rate | The volume of sewage the pump can move per unit of time. | 20-50 GPM |

| Head Height | The vertical distance the pump can lift the sewage. | 10-30 Feet |

| Power Source | Type of energy used to operate the pump. | Electric, Gas, or Solar |

| Material | Composition of the pump, affecting durability. | Cast Iron, Thermoplastic |

| Automatic Features | Controls that manage pump operation automatically. | Float Switch, Level Control |

| Maintenance Frequency | Recommended interval for routine checks. | Every 6-12 Months |

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com