Choosing the right submersible pumps can significantly impact efficiency in various applications, from agriculture to wastewater management. Industry reports indicate that the global submersible pumps market is expected to reach $12.5 billion by 2025, showcasing a 7% annual growth rate. However, not all pumps are created equal, and making the wrong choice can lead to considerable costs and operational issues.

Expert John Smith, a leading figure in the submersible pumps industry, once stated, “Selection is key; an ill-suited pump can cause significant inefficiencies.” This highlights the importance of understanding your specific needs and the characteristics of different pumps. For instance, the size, horsepower, and material used matter greatly in determining a pump's suitability for a particular task.

Many buyers overlook these factors, sometimes opting for cheaper options that may not meet the demands of their operation. Choosing the wrong submersible pump can lead to system failures, costly repairs, or inefficient processes. Careful consideration during the selection process is essential to avoid oversights that could prove detrimental in the long run. Understanding your requirements is not just important; it is crucial.

When considering submersible pumps, understanding their types and applications is essential. Submersible pumps are mainly categorized into two types: drainage pumps and sewage pumps. Drainage pumps typically handle clear water. They are ideal for removing excess water from basements or flooded areas. On the other hand, sewage pumps deal with wastewater. They can manage solid waste and are perfect for septic systems. According to a recent industry report, the global submersible pump market is expected to grow by 6% each year through 2027.

Tips: Identify your specific needs before choosing a pump. Assess the fluid type, required flow rate, and depth for optimal performance.

Another category includes well pumps, which extract water from deep underground sources. They are essential for residential water supply. A study indicates that well pumps account for over 30% of the submersible pump market share. The efficiency and durability of these pumps can impact long-term costs significantly.

Tips: Regular maintenance can extend pump life. Check seals and bearings to avoid potential failures.

Understanding these applications helps in making an informed decision. Selecting the right pump entails careful consideration of your unique requirements and the specific nature of the liquids you will be pumping.

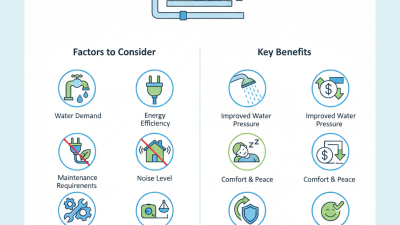

When selecting a submersible pump, several key factors are crucial. The pump's capacity is paramount. A pump's capacity is measured in gallons per minute (GPM). Understanding your specific needs is essential. For example, a home draining system may require a capacity of 40 to 60 GPM. In contrast, larger agricultural applications could need 1,000 GPM or more. Industry data highlights varied needs across sectors.

Next, consider the pump's material. Submersible pumps are typically built with stainless steel or thermoplastic. Stainless steel offers durability and resistance to corrosion. This is especially vital in harsh environments. Thermoplastic can be lighter and typically more affordable. However, it may not withstand extreme temperatures or pressures as effectively. Assessing the environment where the pump will operate is crucial.

Lastly, pay attention to the power source. Most submersible pumps operate on electricity. Some are powered by gasoline or solar energy. Each option presents its benefits and drawbacks. Electrical pumps can offer reliability, while solar options provide sustainability. According to industry reports, nearly 40% of submersible pump users experience issues related to power failures. This calls for careful consideration to prevent interruptions in operation.

This chart outlines the key factors to consider when choosing the best submersible pump for various applications. Each factor is rated on importance from 1 (least important) to 10 (most important).

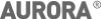

When choosing a submersible pump, understanding the specifications and performance ratings is crucial. Key factors to consider include flow rate, head height, and power consumption. Flow rate measures how much water the pump can move in a given time. Ideally, this should match your needs. Higher flow rates might not always be efficient.

Head height indicates how high the pump can push water vertically. Assess the maximum height you need. If your pump can't reach that height, it won’t be useful. It’s common for users to overlook this detail. Check manufacturer data to avoid disappointment.

Tips: Always consider the material of the pump for longevity. Submersible pumps made from durable materials can endure tough conditions. Also, realize that a higher power consumption often means higher costs. Evaluate your budget carefully. Never choose a pump based solely on the lowest price.

Balancing specifications with your unique needs encourages better choices. Don't rush; take time to reflect on each aspect. What works for one scenario may not fit another. Avoid common pitfalls by conducting thorough research. Be aware that many people end up unsatisfied simply by inadequate assessment.

Submersible pumps are essential in various industries. However, they often require proper maintenance to function optimally. Regular maintenance is not just beneficial; it's necessary. According to industry reports, poor maintenance can reduce pump efficiency by up to 30%. Ensuring your pump runs smoothly involves checking components regularly.

Start with the power supply. A consistent voltage level is vital. Inconsistent power can harm the pump's motor. Additionally, inspect seals and connections frequently. Damaged seals may lead to leaks, causing significant operational issues. A study revealed that neglected seal maintenance leads to up to 25% more energy consumption.

Keep the pump clean and free of debris. Dirt can block the inlet and outlet, reducing performance. Pay attention to the impeller too. A worn or damaged impeller can drastically lower the pump’s flow rate. Consult user manuals for specific maintenance schedules. Skipping regular checks can result in costly repairs or replacements. Balancing efficiency with necessary upkeep is crucial for long-term functionality.

Choosing a submersible pump can be daunting. Many make mistakes that can lead to poor performance. Knowing what to avoid is crucial for making the right choice.

One common error is ignoring the pump's power requirements. Selecting a pump without assessing your energy source can cause inefficiency. Ensure the power source matches the pump's needs. Also, many overlook the importance of checking the maximum depth. A pump that isn’t rated for your water depth can fail quickly.

Another pitfall is neglecting the material quality. Pumps made from inferior materials tend to corrode and wear out faster. Investing in a pump with durable construction is essential for long-term use.

Tips: Always read product reviews to gauge users' experiences. Consider the intended use, whether it’s for clean or dirty water. Take measurements with precision, ensuring you match the pump specifications to your project needs. Reflect on your choices carefully; hasty decisions can lead to costly mistakes.

| Criteria | Description | Common Mistakes |

|---|---|---|

| Flow Rate | The amount of water the pump can move in a given time, usually measured in gallons per minute (GPM). | Not calculating the required flow rate based on your needs. |

| Head Pressure | The vertical distance the pump can lift water. | Ignoring the total head calculation, including bends in the piping. |

| Power Source | The energy type needed, such as electric or gas-powered options. | Choosing a power source unsuitable for your specific location or application. |

| Durability | Material quality and construction that affects longevity. | Not considering corrosive conditions or expected wear and tear. |

| Port Size | The diameter of input/output connections. | Not matching port sizes with existing plumbing systems. |

| Application | Specific use cases such as dewatering, sewage, or drainage. | Selecting a pump that is not suited for the intended application. |

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com