When it comes to selecting the right pump solutions for your specific applications, the choices can be overwhelming. With a multitude of options available, ranging from different types of pumps to various specifications and features, making an informed decision is essential. Understanding the unique requirements of your project, whether it be for industrial use, agriculture, or residential applications, is crucial in narrowing down the options and identifying the most suitable pump solutions.

This comprehensive guide aims to equip you with the knowledge and insights needed to explore the diverse range of pump solutions and their functionalities. Through careful consideration of factors such as fluid characteristics, flow rates, and operating conditions, you will be able to evaluate each option effectively. By comparing different types of pumps, their designs, and applications, our goal is to empower you to make choices that enhance efficiency, reduce costs, and ensure reliability in your operations. Join us as we delve into the intricacies of choosing the best pump solutions tailored to your needs.

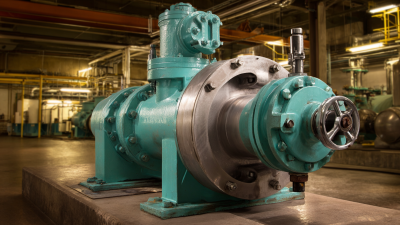

When selecting the best pump solutions for specific needs, it's crucial to understand the different types of pumps and their applications. Centrifugal pumps, for instance, are widely used in various industries due to their ability to move fluids efficiently through a rotating impeller. These pumps are ideal for applications that require the transport of large volumes of liquids at low to moderate pressures, such as in water supply systems, irrigation, and chemical processing.

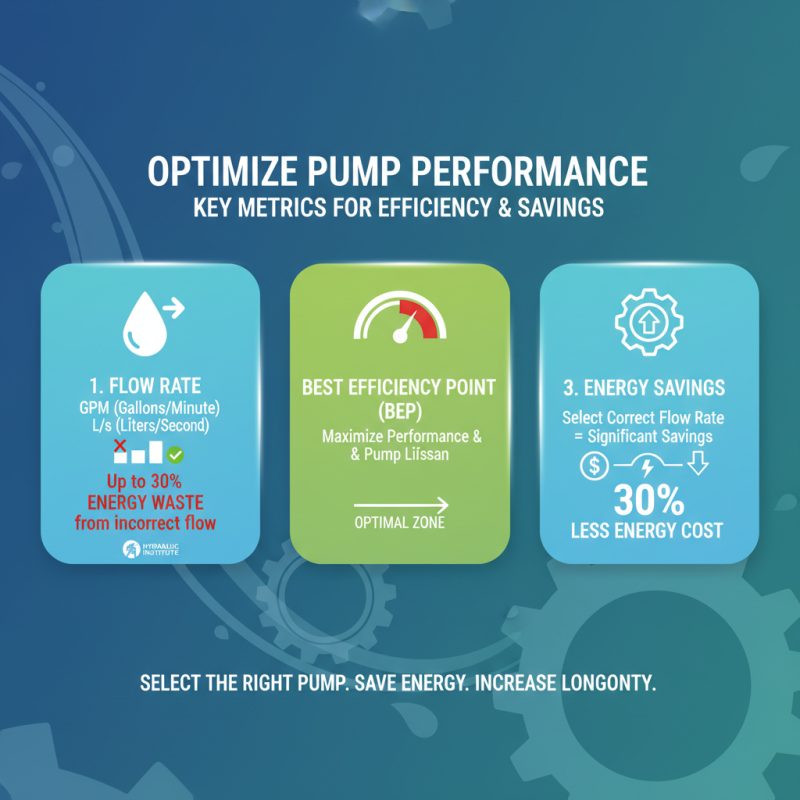

On the other hand, positive displacement pumps offer a distinct mechanism that can be advantageous in different scenarios. They operate by trapping a fixed amount of liquid and forcing it through the discharge pipe, making them suitable for high-viscosity fluids or applications that require precise flow rates. Common uses for positive displacement pumps include food and beverage processing, pharmaceuticals, and oil transfer. Understanding these basic distinctions ensures the right pump type is chosen based on the specific requirements of the application, such as fluid characteristics, desired flow rate, and discharge pressure.

This chart illustrates the efficiency ratings of various types of pumps commonly used across different industries. The data showcases the applications of centrifugal, diaphragm, and screw pumps based on their flow rates and suitability for various tasks.

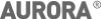

When evaluating pump performance, understanding key metrics is essential to selecting the right pump solution for your needs. One of the primary metrics to consider is the pump's flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s). According to a report by the Hydraulic Institute, selecting a pump with the correct flow rate can lead to significant energy savings, with estimates suggesting that incorrect flow rate selection can increase energy consumption by up to 30%. Ensuring that the pump operates near its Best Efficiency Point (BEP) can optimize both performance and longevity.

Another critical performance metric is the Total Dynamic Head (TDH), which accounts for the energy required to overcome both static lift and friction losses in the system. A comprehensive analysis by the American Society of Mechanical Engineers indicates that understanding TDH can prevent under-sizing or over-sizing of pumps, leading to operational inefficiencies and increased maintenance costs. Additionally, pump efficiency, often expressed as a percentage, directly correlates with energy consumption and operating costs. Selecting a pump with higher efficiency ratings not only enhances performance but also contributes to lower operational expenses over time, affirming the need for careful evaluation of these key characteristics when choosing pump solutions.

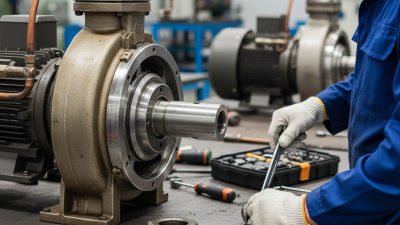

Identifying your specific pumping requirements and conditions is crucial for selecting the best pump solutions for your needs. The first step in this process is to determine the nature of the fluid you will be handling. According to the Fluid Admin Association, fluid characteristics such as viscosity, temperature, and pH can significantly influence the performance of a pump. For instance, highly viscous fluids require specialized pumping solutions like positive displacement pumps that provide the necessary flow rates without damaging the fluid's integrity. Additionally, understanding the chemical composition of the fluid ensures compatibility with pump materials, preventing premature wear or failure.

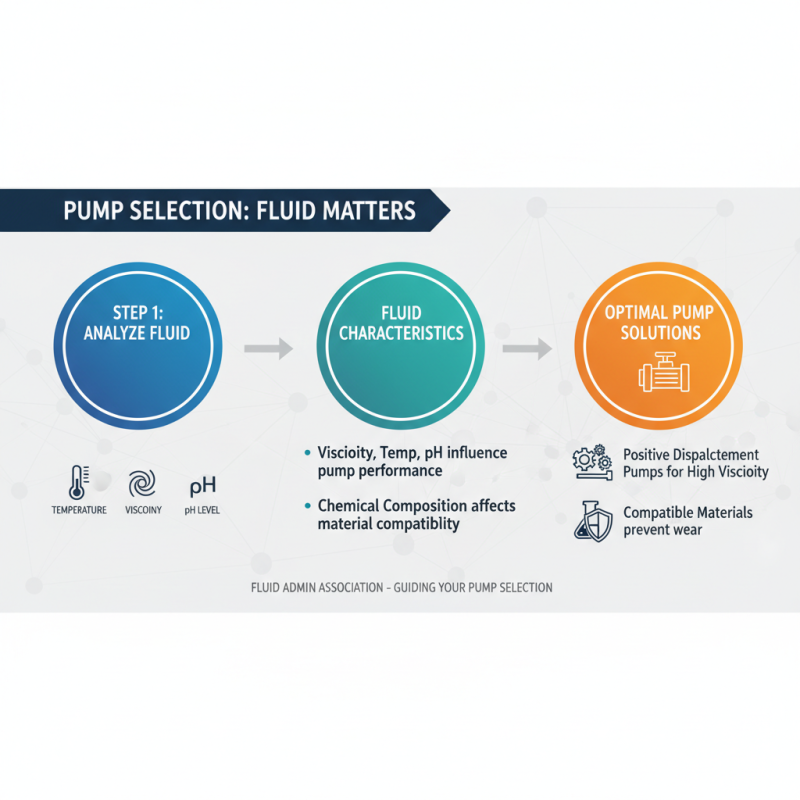

Another essential factor to consider is the operational environment where the pump will be installed. The Global Pump Market Report 2023 indicates that factors such as ambient temperature, humidity, and potential exposure to corrosive elements must be evaluated to ensure optimal performance and longevity of the pumping system. For example, if a pump will be used in a harsh chemical environment, it is vital to select corrosion-resistant materials that can withstand prolonged exposure. Moreover, assessing the required flow rate and head pressure for your specific application will help further narrow down the options, ensuring the chosen pump operates efficiently within the desired parameters. This tailored approach can lead to reduced operational costs and increased reliability in the long term.

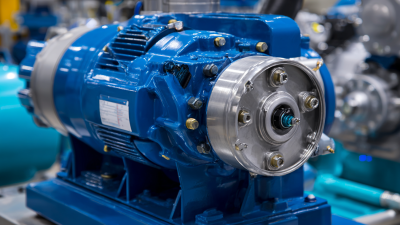

When selecting a pump solution, energy efficiency and operational costs are critical factors that can significantly impact both the environment and your bottom line. An energy-efficient pump not only reduces electricity consumption but also lowers greenhouse gas emissions. To assess energy efficiency, one must consider factors such as the pump's design, the type of motor used, and the overall system configuration. Variable frequency drives (VFDs) can enhance energy efficiency by allowing the pump to operate at varying speeds, ensuring that it only uses the power necessary for the current demand.

Operational costs encompass more than just energy expenses; they include maintenance, installation, and potential downtime during operation. It is essential to evaluate the total cost of ownership over the pump's lifespan rather than the initial purchase price alone. High-quality materials and advanced technologies might lead to higher upfront costs but can result in lower maintenance needs and longer service life. Furthermore, optimizing the system for specific operational conditions can yield substantial savings. By carefully analyzing energy efficiency and operational expenses, one can identify the best pump solutions tailored to meet both performance and cost requirements.

| Pump Type | Energy Efficiency (%) | Operational Cost ($/year) | Maintenance Frequency (times/year) | Lifespan (years) |

|---|---|---|---|---|

| Centrifugal Pump | 85 | 1200 | 2 | 15 |

| Positive Displacement Pump | 90 | 1500 | 3 | 20 |

| Submersible Pump | 80 | 1400 | 2 | 10 |

| Diaphragm Pump | 87 | 1600 | 1 | 12 |

| Gear Pump | 92 | 1300 | 2 | 18 |

When selecting a pump solution, the importance of choosing the right supplier and service support cannot be overstated. A reliable supplier will not only provide pumps that meet your specific operational needs but also offer expertise in helping you navigate technical specifications and regulatory standards. Look for suppliers with a proven track record in the industry, as their experience can significantly impact the efficiency and reliability of your pump systems. Additionally, consider their ability to recommend products that are suited to your application's unique challenges, which can save time and resources in the long run.

Service support is another critical aspect to consider in your decision-making process. A comprehensive service plan ensures that your pumping systems remain operational and efficient throughout their lifespan. This includes access to maintenance services, emergency repairs, and technical assistance. Having a support team familiar with your equipment enables faster response times and minimizes downtime. Therefore, when evaluating potential suppliers, inquire about their after-sales support and maintenance programs, as these factors can greatly enhance your overall pumping solution experience.

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com,

sale@harbertpump.com